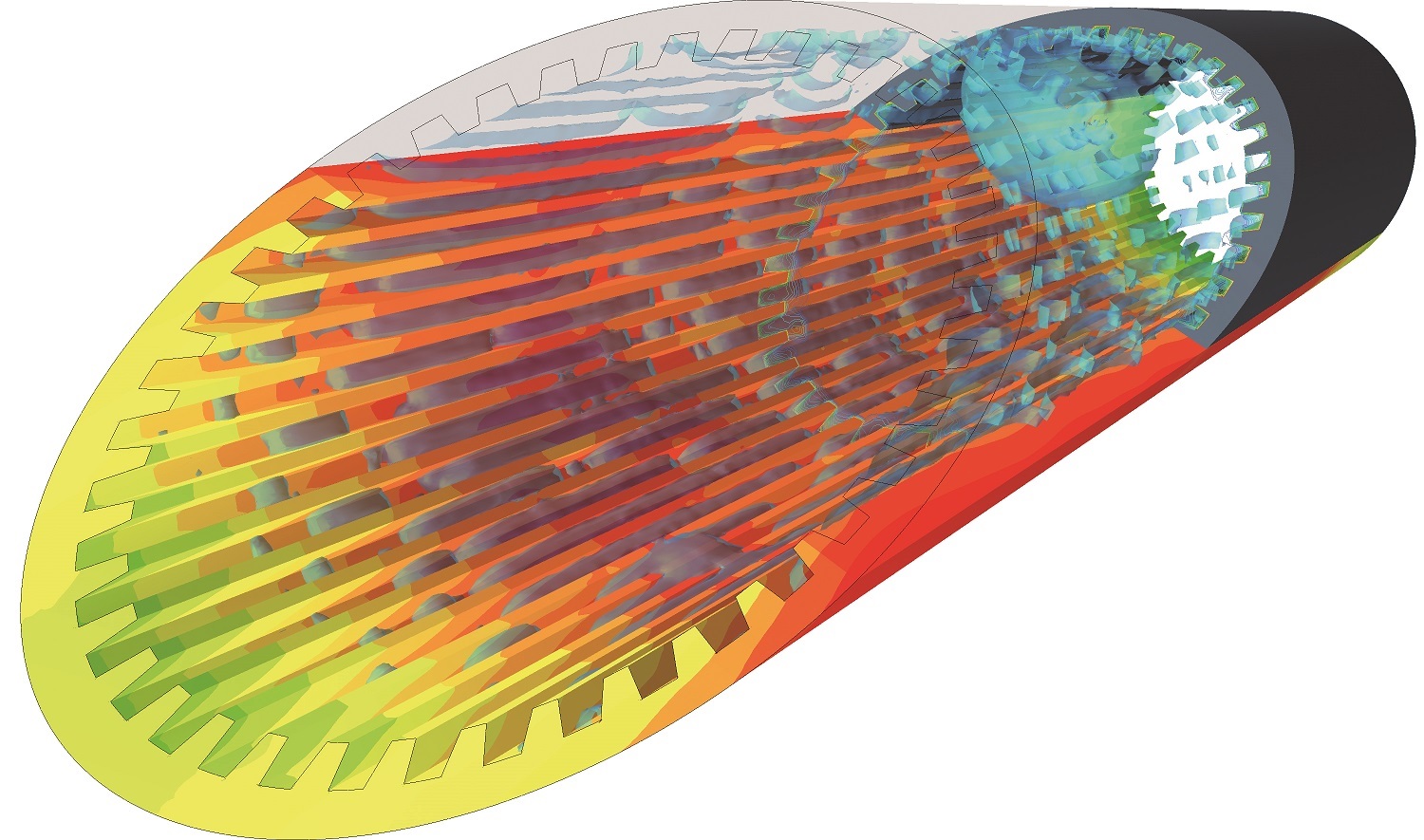

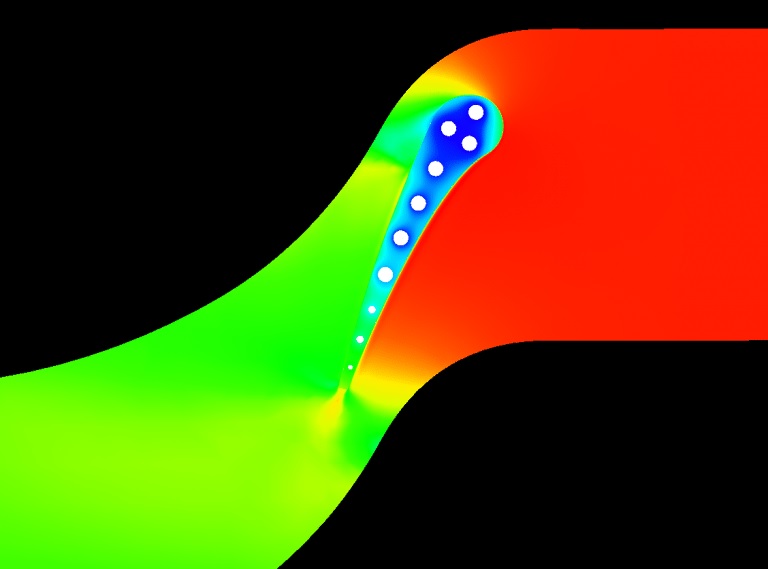

Designing turbomachinery components such as axial turbines, axial pumps, centrifugal compressors, centrifugal pumps, and mixed flow compressor/turbine requires a deep understanding of fluid dynamics, thermodynamics, and mechanical engineering principles. By leveraging CFD and FEA tools, it is possible to optimize designs for improved performance, efficiency, and reliability.

Axial turbines convert the energy of a fluid into rotational energy, while axial pumps do the opposite, converting rotational energy into fluid flow. Centrifugal compressors increase the pressure and density of a gas by imparting kinetic energy through the use of a rotating impeller. Centrifugal pumps use a similar mechanism to move fluids from one location to another. Mixed flow compressor/turbines combine features of both axial and centrifugal designs to provide a unique combination of performance characteristics.

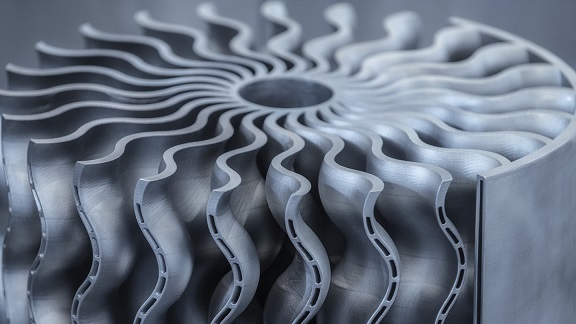

By using CFD and FEA tools, it is possible to design these components with a wide range of features, including pre-loaded profiles, prismatic or twisted blades, multiple extractions/injections, inter-stage heat exchangers, Curtis & Rateau stages, impulse & reaction designs, drilled and reamed nozzles, and partial admission. This allows for a high degree of customization and optimization to meet the specific needs of each application.